Advanced Watchmaking Tools Guide

Watchmaking is a tool lover's paradise, and there is a nearly endless variety of specialty watchmaking tools out there for dedicated horologists. Below is a selection of some of the more advanced tools that I actually use in my workshop, along with basic tools, on a regular basis. This is a personal guide based on my own watchmaking practice, and it certainly doesn't even begin to cover the full gamut of available watchmaking tools, or even everything that I have squirreled away in my various toolboxes. It should cover most situations that you may encounter working on typical watch movements and give you an idea of tools you may want to invest in as you advance more deeply down the watchmaking rabbit hole.

Please note that this guide focuses on watch movement servicing and repair, and doesn't delve into certain tools and materials that I use for case restoration work, which will be covered separately in my Case Restoration Guides.

Contents

Vision, Inspection, and Measurement

Advanced Vision Tools

Few things are as important or as worthy of investment as good vision when working on tiny watch components. High quality optics can make a huge difference in how easily you can manipulate watch parts.

Stereo/Trinocular Microscope

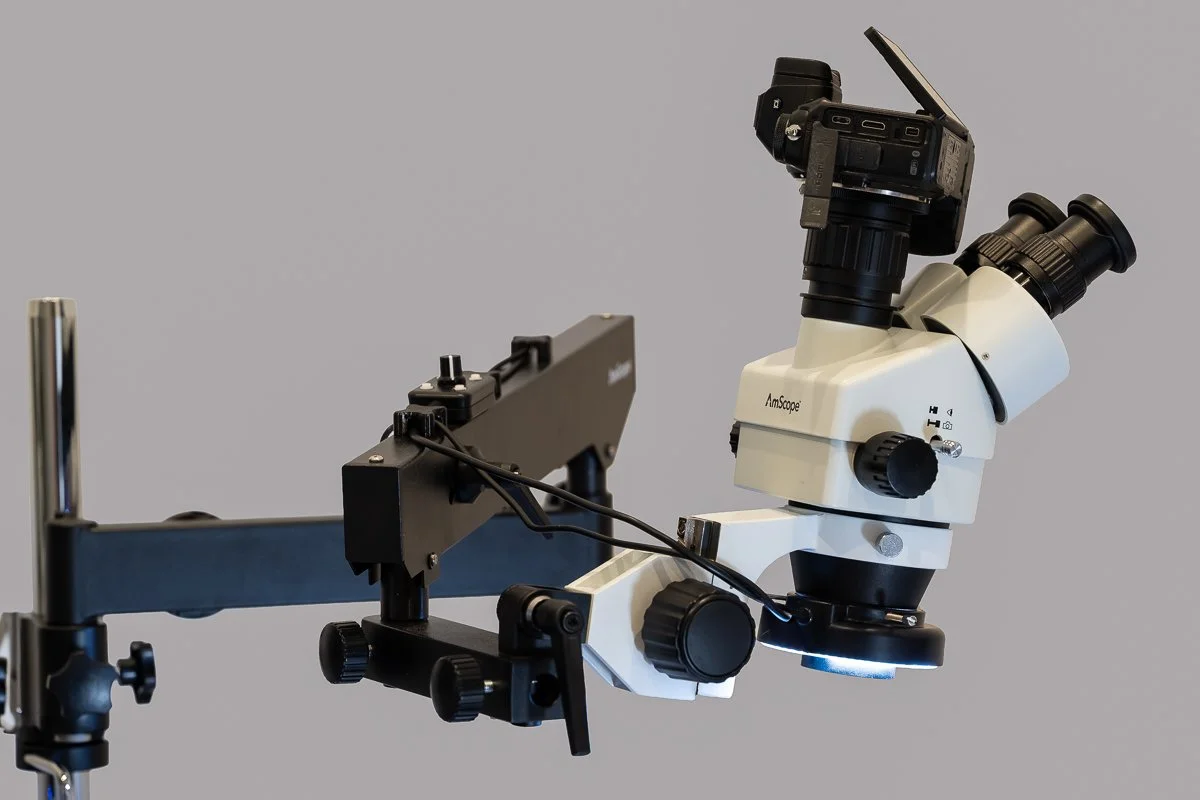

I iterated through several inexpensive monocular digital inspection microscopes before investing in a high-quality trinocular zoom microscope. The real difference maker here, aside from the quality of the optics, is the added depth perception, allowing you to easily judge distances and work in three dimensions. The ability to easily zoom in and out by turning a knob while (mostly) maintaining focus is also a great quality of life improvement over cheaper solutions. The trinocular port allows mounting of a camera, which is handy for capturing images and video of your work, although the cheaper digital scopes actually excel at this and are easier to use.

My scope is from AmScope, although there are a number of other high (or even higher) quality options available, depending on your budget. Make sure to look for a mounting option that functions well with your workbench setup. My scope is on a long, heavy duty articulated boom that clamps to the back side of my desk. This allows me to easily adjust the position of the scope, and push it out of the way entirely when not in use while keeping my work area clear of obstructions and making sure the scope is steady while in use.

My AmScope trinocular microscope in its boom arm mount. There is a Nikon DSLR currently attached to the trinocular port

Endoscope

Occasionally, you'll need a magnified view from the side, rather than the top. In some cases you can just tilt the movement and continue to use your main microscope, but this isn't always possible or practical. One solution that I often use is to fall back to a classic loupe, but another option is to use a USB endoscope camera. These are inexpensive, flexible cameras that connect to your computer via USB and provide a magnified view, potentially from odd or difficult angles. They typically come with built-in illumination. The image quality is not as good as a dedicated microscope or loupe, but they can occasionally be very useful, especially in conjunction with a stand to hold the endoscope steady at the appropriate angle.

USB Endoscope on Adjustable Stand

Measuring Tools

Accurate measurement is crucial in watchmaking, particularly when selecting appropriate replacement parts. Keeping a good set of accurate measuring tools handy is essential as you extend your watchmaking capabilities.

Calipers and Micrometers

A good set of calipers is probably the most versatile and frequently used measuring tool in a watchmaker's toolkit. A well made, accurate set can be used to measure everything from watch band sizes to mainspring dimensions to pivot diameters. It's worth investing in a high-quality set, which will last a lifetime if properly cared for. While traditional dial-based calipers will get the job done, I recommend going for a digital set, since these are easier to read and have nice features like zeroing at any position and switching between metric and imperial units.

A micrometer is a good secondary tool. These are typically more accurate than calipers, particularly when measuring small objects, but significantly less versatile. I find myself reaching for my micrometer most often when measuring small pivots, pinions, and other cylindrical components where high accuracy is required. If you can get hold of a bench micrometer with a support anvil, these can make measuring small parts much easier. If not, a micrometer stand can help stabilize things.

The digital calipers and micrometer that I use for my watch work

Pin Gauges

Pin gauges are small, precisely sized cylindrical rods that are used to measure the diameter of small holes and pivots. They come in sets with a range of sizes, typically in increments of 0.01mm or 0.001 inches. They can be used for measuring pivot diameters, jewel hole sizes, and other small cylindrical features. While they are somewhat specialized, they are quite useful to have on hand for certain tasks. For example, since they are typically solid steel, they can be used as a more precise alternative to a smoothing broach to prevent over-tightening of cannon pinions when using a staking set by inserting the appropriate size pin gauge into the cannon hole while tightening.

Microscope Calibration Scale

If you do a lot of work under a microscope, having a calibration scale is very useful for quickly estimating the size of small components and features. These scales typically consist of a small glass slide with finely etched lines and markings that can be placed under the microscope for reference. They can be used directly for measurement in some cases, or alternatively to calibrate software tools that can be used to measure components in microscope images.

Microscope Scale with 0.1mm Resolution

Crown/Stem Tap Size Tool

This is more of a convenience tool than a necessity, but if you work on a lot of watches with different crown and stem sizes, having a dedicated tap size tool can make it easier to quickly identify the correct size for replacement parts. These tools consist of a small block with a series of threaded holes and posts that correspond to common crown and stem sizes. They tend to be a bit spendy for what they are (at least, the common Bergeon model is), but can save time, hassle, and uncertainty when sourcing replacement crowns.

Bergeon 6740 Crown and Stem Sizing Gauge

Powertrain and Core Disassembly & Assembly

Mainspring Winders

They're expensive, single purpose, and often fiddly to use, but eventually every aspiring watchmaker will want to invest in a good set of mainspring winders. Once you get the hang of using them, they make the process of installing mainsprings into barrels much easier and safer for both you and the mainspring. They're not a panacea, and you will encounter situations where you'll need to hand wind a mainspring into a barrel, but for most standard mainsprings these tools are well worth the investment.

I have a full set of Bergeon mainspring winders, which cover a wide range of mainspring sizes (both right and left wound), but, if you want to start smaller, you can get by with a more limited set of winders that cover the most common sizes. I find that the #5 (8.6mm), #6 (9.8mm) and #7 (10.8mm) winders are by far the most commonly used for most vintage watches. Left hand wind mainsprings are also uncommon, especially if you mostly work on Swiss movements, so getting the above winder sizes for right hand mainsprings only will get you a long way.

I recommend springing (no pun intended) for the "real deal" Bergeon items, rather than cheaper knock-offs, because the quality and precision of the tools really matters. It's a big investment, but if you take good care of them, you won't have much trouble selling them for a good price if you ever decide to change hobbies.

The Bergeon 5356 Mainspring Winder Set that I use has a broad selection of sizes for both right and left hand winding mainsprings

Staking Set

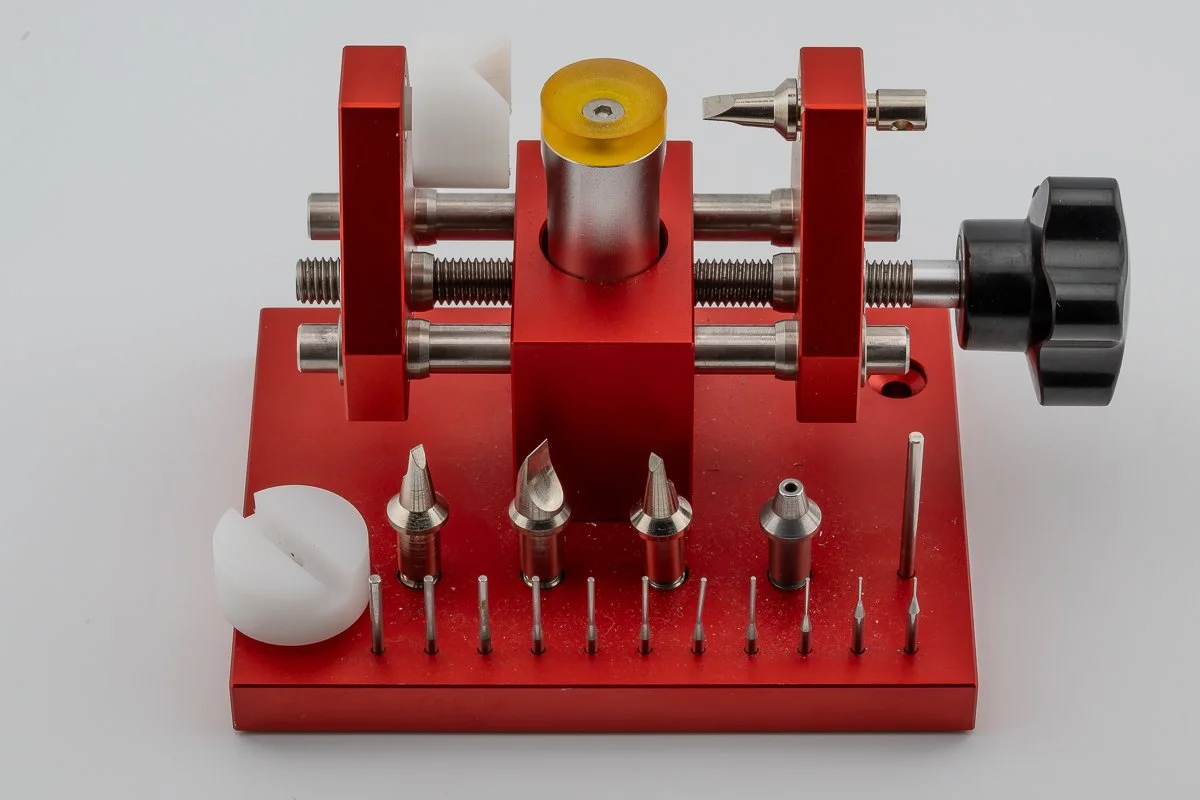

When it comes to advanced watch repair operations, no tool in the watchmaker's arsenal is as versatile and valuable as a good staking set. A staking set is essentially a collection of various punches, stakes, and other tools that fit into a common staking anvil, allowing you to perform a wide variety of tasks, including Balance Staff Removal and Installation, collet and cannon pinion tightening, end shake adjustment, riveting, and much more. Stakes are typically applied by tapping the end with a small jeweler's hammer, although some high end staking sets also have hand press attachments with a micrometer stop for more precise and delicate work.

Realizing it was something I needed, I originally purchased a relatively inexpensive generic staking set on AliExpress, but found the quality and durability to be lacking. I eventually upgraded to a vintage Kendrick & Davis (K&D) staking set, which is extremely high quality, comes with a broad variety of components, and still performs flawlessly after decades of use. If you're serious about watchmaking, and you're ready to move beyond simply replacing components to really fixing things, a high-quality staking set is a must-have investment for your toolkit.

My vintage K&D staking set is an extremely versatile tool

Jeweling Tools

Eventually every watchmaker will need to remove, reinstall, or replace pivot jewels in watch movements, either because the jewel is damaged, or simply because (as in many older pocket watch movements) the jewels need to be removed for proper cleaning. while you can get away with using a staking set and some improvised tools for basic jewel work, a dedicated jeweling tools make these tasks much easier and more reliable.

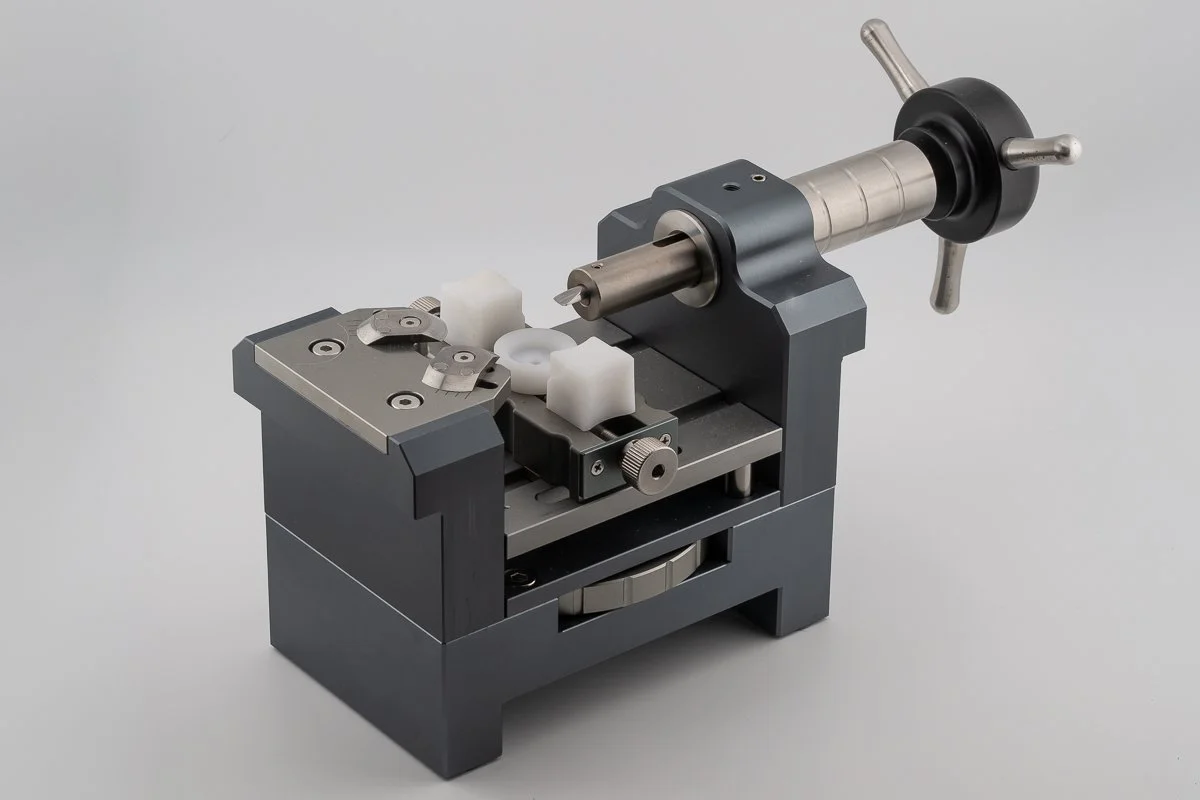

Jeweling Press

A jeweling press is a specialized tool that allows you to precisely and safely remove and press pivot jewels into place in watch plates and bridges. They come with a variety of interchangeable dies to accommodate different jewel sizes. The top die typically has a spring loaded centering pin that engages with the hole in the jewel to ensure proper alignment during installation, while the bottom die engages with the watch plate but has a large enough hole to allow the jewel to pass through. Micrometer stops allow new jewels to be installed to a precise depth. There are a couple of different designs available, including lever operated (Horia-style) and screw operated (Seitz-style) models. While primarily intended for jewel work, some watchmakers like to use them for certain operations that would normally involve a staking set, such as installing roller tables, as they can provide a somewhat more controlled and precise way to apply pressure.

I use a Seitz-style screw operated model, which I find to be more precise and easier to control than lever operated options. This is one area where I can recommend relatively inexpensive Seitz-replica options such as those available on AliExpress, as they seem to work quite well for typical applications.

My relatively inexpensive Chinese-made Seitz Jeweling Press clone works quite well

Jewel Pusher

Older vintage movements, particularly pocket watch movements, often have balance and other pivot jewels brazed into brass settings that are simply pressed into place then retained using small screws.These jewels can be a bit tricky to remove without damaging them or the surrounding metal. A jewel pusher is a simple hand tool that allows you to safely and easily push these jewels out of or back into their settings. They have a slightly concave tip that fits around the jewel and allows you to apply even pressure onto the setting without damaging the jewel itself.

Given the association with older movement styles, I'm not sure if they actually make these things any more, but you can still find inexpensive vintage examples for sale on eBay, and it's a handy tool to have around if you work on older watches.

My cheap vintage jewel pusher has been surprisingly useful, especially when working on old pocket watches

Presto Tools

Presto was a Swiss company that made a variety of specialized watch repair tools. While the company is no longer in business, many of their tool designs live on through various modern manufacturers, including Bergeon. In particular, the Presto line of small, spring-loaded specialty removal tools still find an important place in many watchmakers' toolkits.

Presto Cannon Pinion Remover

If there's one Presto-style tool to have in your kit, this is it. It's designed specifically to remove cannon pinions, something you will have to do frequently when servicing watch movements, and it does the job quickly, easily, and safely. Moreover, its design makes it useful in other situations where you need to remove small press-fit components. There are more elaborate and expensive cannon pinion removers available, but I've never seen the need for anything more than this simple and effective tool.

Presto Wheel Removers

These spring-loaded tools are designed to safely and easily remove press-fit wheels such as those found in chronographs or certain movements with indirect-drive center second mechanisms (a requirement for disassembly of these movements). They work by gripping the wheel from both sides and pulling it straight off its arbor, minimizing the risk of damage to the wheel. There are two styles, one for five spoke and another for six spoke wheels, although I have found that you can generally finesse the six-spoke tool to work with five-spoke wheels as well. You won't be using these nearly as often as the cannon pinion remover, but it's very easy to damage or warp delicate wheels and scratch bridges when trying to remove them with improvised or alternative tools (e.g. tweezers, screwdrivers or hand levers) so having a proper wheel remover is a worthwhile investment.

Presto Hand Remover

These tools are designed for safe watch hand removal, but while they can certainly be used this way I tend to reach for my hand levers much more often for this task. Where I find the Presto hand remover more useful is in situations where I need to remove small press-fit components where the only available leverage point is the post on which they are mounted. An example would be removing the pinion from the offset direct drive intermediate wheels found in some movements. In these situations, the Presto hand remover can be a useful tool to have... on hand.

There are several versions of this tool available, but I have found that the modular version (with 4 rotating tips) is the most versatile, particularly for applications that do NOT involve removing watch hands.

My personal collection of Bergeon Presto-style tools: The cannon pinion remover (green handle), 5-spoke wheel puller (blue handle), 6-spoke wheel puller (red handle), and modular hand puller (orange handle)

Broaches & Files

At some point on your watchmaking journey, you'll likely find yourself needing to smooth, shape, or refine various metal components & surfaces. Broaches and files are essential tools for these tasks.

Smoothing Broaches

Smoothing broaches are tapered, cylindrical tools with fine abrasive surfaces that are used to smooth and polish the inner surfaces of holes and other small openings in watch components. They come in sets and are inexpensive. In addition to their intended use, they also work well whenever you need a small metal "post" to hold parts - for example to hold cannon pinions while tightening them with a staking set.

Cutting Broaches

Cutting broaches are similar to smoothing broaches, but have a much more aggressive surface for removing material. They are useful for enlarging or shaping holes in watch components, and while they are less commonly needed than smoothing broaches, they are essential for certain tasks. They're also readily available and inexpensive, so it's worth having a set on hand.

Jeweler's Files

Jeweler's files are small, precise files that are used for shaping and refining metal components. They come in a variety of shapes and sizes, including flat, round, half-round, and triangular profiles. Jeweler's files are potentially useful for a variety of tasks working with both movements and cases. It's worth investing in a high-quality set; I use a set by Grobet USA, which have been excellent.

Case and External Hardware

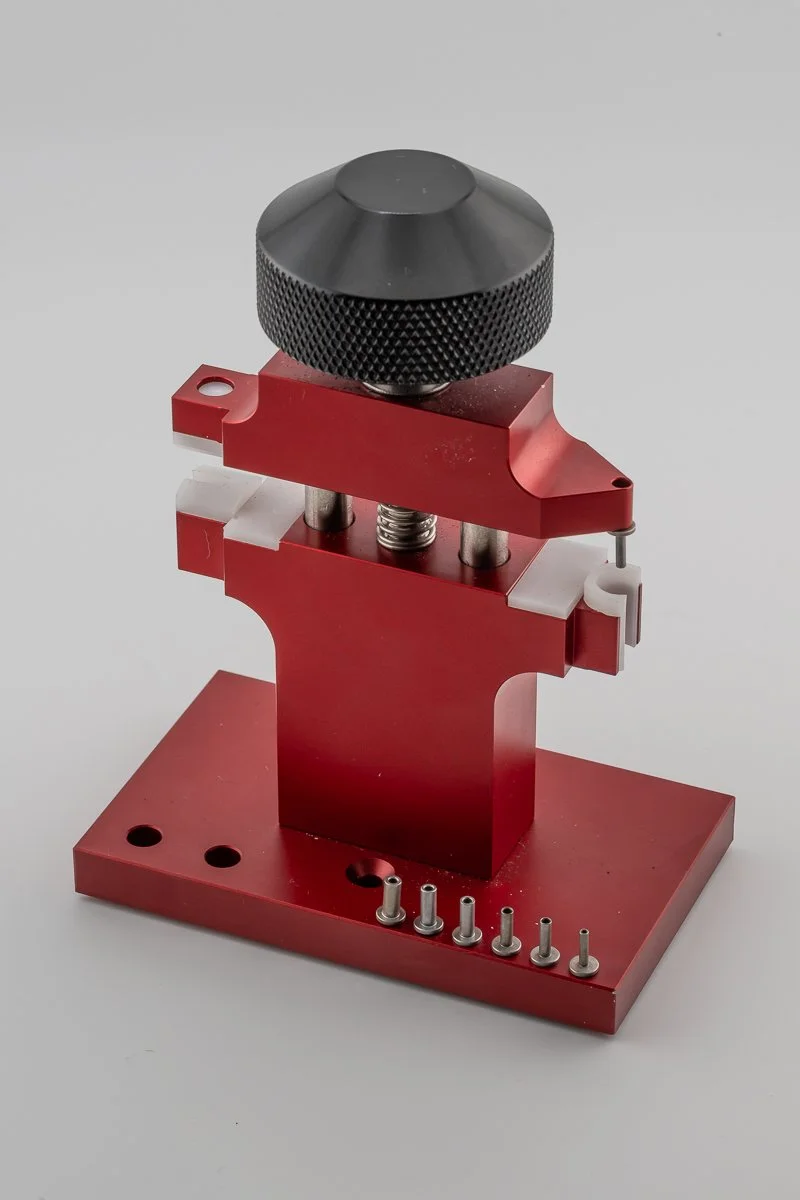

Watch Press

A watch press is a tool used to safely and evenly press watch crystals, case backs, and other components into place without damaging them. It typically consists of a frame with interchangeable dies that match the size and shape of the parts being pressed. The dies are usually have plastic or nylon working surfaces to prevent scratching or damaging delicate components.

Personally, I use a high quality Crystal Lift for most acrylic watch crystal installation tasks, but I still bring out the watch press when I need to install a tension ring or press-fit glass or sapphire crystal. It's also useful for seating certain bezels and stubborn snap-on case backs.

Beware of the least expensive watch press options, which may not be sufficiently rigid or precise to function reliably and apply even pressure. You don't need to spend a fortune for something from the high end Swiss manufacturers, but you should nonetheless look for a model that is solidly built. My first watch press, purched on AliExpress, was not very well made, and the main arm supporting the press actually started to deform. Now I have another AliExpress press that, while considerably more expensive, is built like a tank and a joy to use. Just goes to show that sometimes you actually do get exactly what you pay for.

I use a watch press that, while of generic Chinese manufacture, is very well made, precise, and reliable. I particularly appreciate the compound aluminum/nylon dies, which are rigid but don’t scratch cases or crystals.

Crystal Lift

A crystal lift is a specialized tool used to remove and install acrylic watch crystals. It has a number of claw-like arms that grasp the crystal from the edge and can apply sufficient pressure to allow it to be easily removed and reinserted without damaging the crystal or the watch case. Crystal lifts can remove crystals while the movement is still in the case, and thus they are essential for working on certain watches with monobloc cases that can only be accessed by removing the crystal. That said, this capability makes them quite useful in other situations - for example, if you need to adjust the watch hands but don't want to fully remove the movement from the case: you can simply remove the crystal with the crystal lift, adjust the hands, then reinstall the crystal.

While there are relatively inexpensive options out there which may be adequate for occasional use, this is one tool where I think it really pays to make an investment in a precisely manufactured, high-quality model such as those made by Bergeon. While it was expensive, my Bergeon crystal lift works so well that it has largely replaced my watch press for acrylic crystal installation tasks, and it is much quicker and more convenient.

My Bergeon 6400 Crystal Lift is sufficiently precise and well made enough for much more than occasional use, and has replaced my watch press for most crystal installation tasks

Specialty Case Back & Bezel Removal Tools

While we covered some basic, inexpensive options for case back and bezel removal in my Basic Tools Guide, as you get a bit deeper into watchmaking you'll likely want to invest in some more advanced, specialized tools for these tasks.

Screw On Case Back Tool

Simple handheld caseback removal tools or even the ever-useful rubber ball can get the job done in many instances, but eventually you'll want to invest in a more robust and precise benchtop setup for dealing with screw on case backs that allow you to safely apply more pressure when dealing with stubborn casebacks. Benchtop case back openers typically have adjustable jaws that can be set to fit a wide variety of case back sizes & configurations, and a sturdy adjustable base with inserts to hold the watch case securely in place while you work. You can typically also get specialty inserts for brands that use non-standard case back designs, such as Rolex.

I have had good success with moderately priced tools from AliExpress, so there's no need to spend a fortune to get a reliable setup.

My heavy duty caseback removal tool will take care of even the most stubborn casebacks, as long as you can find a pair of jaws that engage positively with the caseback. This tool also came with a set of Rolex-compatible inserts.

Snap On Case Back & Bezel Removal Tools

Snap on case backs and bezels can be particularly tricky to remove without damaging them or the watch case. While simple case back knives can work in many situations, a more specialized tool can make more difficult jobs much easier. There are a number of tools available that are specifically designed for removing snap on case backs and bezels with a wide variety of designs and price points. I have several that I use in different situations.

These tools all work a bit differently, but one thing I'll say is that they can potentially generate a lot of force, so be a little careful when using them to avoid damaging delicate case components. If the part you are trying to remove seems exceptionally stubborn, stop and reevaluate what you are doing. I once effectively destroyed a vintage Girard-Perregaux snap back case that had a very delicate, hidden gasket recess immediately beneath the caseback lip using one of these tools without sufficient care.

I have accumulated a couple of different snap on caseback and bezel removal tools. The red tool on the left is inexpensive, but works pretty well and is quite versatile, including tools for removing pins from bracelets. The tool on the right is a knockoff of the Bergeon 9820. It was much more expensive than the red tool, although much cheaper than the original Bergeon, and is MUCH better built and more precise.

Case Tube & Pusher Tools

Most watches have a steel case tube that fits into the case and helps to locate the crown and stem. These are generally separate, removable components that can be replaced if worn or damaged. Chronograph or other pushers also have bodies that screw or press into the watch case. Removing these components is useful not only for replacement purposes but when restoring cases, as they need to be removed for proper polishing and refinishing. There are specialized tools to assist with this which may be a good addition to your toolkit.

Case Tube Press

While there are some (typically high-end) watches that have screw-in case tubes, most use press-fit case tubes that require a specialized case tube press tool for safe removal and installation. A case tube press consists of a movable frame with interchangeable dies designed to mate with the back of the case tube and push it out of the case from the inside. There is usually a separate side used to help press the tube back into the case for installation purposes.

While specialized in nature, this is a relatively inexpensive tool that is well worth having if you plan to do any case restoration work.

My AliExpress case tube tool. It’s cheaply made, but it gets the job done

Threaded Case Tube Wrench

Threaded case tubes and screw in watch pushers require a specialized case tube wrench for safe removal and installation. This compact hand tool typically comes with multiple heads that are designed to grip internal splines in the case tube or pusher body securely, allowing you to unscrew or tighten these components without damaging them. While not as commonly needed as a case tube press, it's a useful tool to have if you work on watches with threaded case tubes or pushers.

A basic wrench for threaded case tubes and pushers with various interchangeable splined heads

Balance, Escapement, and Regulation

Specialty Balance Tools

The watch balance is one of, if not the most, critical components in the entire watch, and sooner or later, if you are passionate about making your watches run well, you'll be dealing with performance issues that may require disassembly, adjustment, or repair of the balance assembly. While most operations involving the balance are delicate and potentially challenging, there are a number of specialized tools that can make working with balances easier and more effective.

Balance Tack

A balance tack is a specialized holder that allows you to securely hold a watch balance assembly while working on it outside of the movement. It typically consists of a small base with a vertical post with a narrow tip that fits into the balance cock screw hole, allowing the balance to dangle from the cock by the hairspring (while I have seen some folks express concerns about this, the balance generally isn't heavy enough to damage the hairspring even when suspended in this manner). Some more elaborate models come with an adjustable platform to support the balance, often with small cutouts for the impulse jewel. There are various inspections and operations you can perform more easily with the balance on a tack, and it's a cheap tool, so other than the risk of poking yourself with the sharp end, there's really no reason not to acquire one.

Hairspring Collet Tools

On movements without an adjustable stud carrier, correcting the beat error can only be accomplished by rotating the hairspring collet around the balance staff. While this can be done by inserting a small screwdriver into the collet slot, it is a very delicate operation (especially so if you attempt the time saving approach of slipping your tool between the hairspring coils while the balance is still attached to the balance cock while suspended on a balance tack). Even a small slip can result in damage to the inner coils of the hairspring which can be difficult or impossible to repair. A hairspring collet tool is specialized tool that fits around the balance staff and has a small tooth that engages with the collet slot, allowing you to precisely rotate the collet with much less risk of damaging the hairspring. The downside is that these little tools are quite specialized and thus somewhat expensive for what they are. They come in different sizes to fit different balance staffs, so make sure to get the right size for your movements. I have found that the 1.1mm size is the most useful for typical wristwatch balances.

The tip of a hairspring collet tool. The hole fits around the balance stem while the triangular tooth fits into the gap in the hairspring collet, allowing it to be rotated with precision and relative safety.

Roller Table Removal Tool

If you need to disassemble the balance (typically to replace a broken balance staff), part of the process involves removing the roller table, which holds the impulse jewel and which is generally friction-fit onto the balance staff. Using a dedicated roller removal tool is definitely recommended to avoid potential damage to either the roller table or the balance wheel. There are many different styles of these tools available, ranging from simple hand tools to more elaborate staking set attachments, but my personal favorite is the Bergeon 2810, which is simple and easy to use but quite effective. There are cheap generic versions of this tool available, and, given its simplicity, they may work fine, but I haven't tested them.frequently.

I use this Bergeon 2810 Roller Table Removal Tool and it has been both easy to use and reliable

Specialty Balance Staking Punches

When working on balance staffs, there are a number of specialized staking punches that can make your life easier. These include balance staff removal collet tightening punches. For example, I use a specialized removal punch that incorporates a spring-loaded mechanism that stabilized the balance wheel while applying force to the staff for removal. This prevents potential distortion of the balance wheel during the removal process, which is a common issue. These sorts of specialized punches were much more common in the heyday of mechanical watchmaking, but functional vintage versions can still be found on sites like eBay, and they are worth having if you plan to do balance staff repairs.

Balance Poising Tools

Removing and replacing balance components has the potential to result in a balance that is out of poise, which can potentially affect timekeeping accuracy. Balance poising tools help you identify and correct these imbalances by allowing you to measure and adjust the weight distribution on the balance wheel to ensure rotational symmetry for optimal performance.

Regulation Adjustment Tools

While most regulation adjustments can be made using standard tweezers or a plastic point stick, I've found that it's helpful in some cases to have a specialized tool to adjust regulator arms (as well as adjustable stud carrier arms). I wasn't able to find an off-the-shelf tool for this, but I was able to create one by filing down an inexpensive springbar tool that came with one of my bands. The small notch in the tool engages with the regulator arm and makes it a bit easier to make small adjustments.

In addition, some movements have specialized regulation mechanisms that require dedicated tools for precise adjustment, such as Etachron regulators or Rolex's proprietary Microstella regulation system. If you work on movements with these features, it's worth investing in the appropriate tools to ensure accurate regulation.

My home made regulator adjustment tool. The notch on the end provides a stable interface for adjusting both regulator arms and adjustable stud carrier arms

Pivot polishing sticks

Thank Mark Lovick for this one: one quick and easy way to get a bit of extra amplitude out of a balance, particularly when you have it removed from the balance cock or bridge, is to polish the pivots with fine jewelry polishing sticks. These are cheap, so I always keep a handful around. Of course, they can actually be used for more than just balance pivots, but that's how I use them most frequently.

Demagnetizers

Magnetism is the enemy of accurate timekeeping in mechanical watches, and even small amounts of magnetism can potentially affect a watch's performance. Magnetization of your tools or small parts is also a headache that can make them difficult to manipulate. A demagnetizer allows you to quickly and easily remove unwanted magnetism from watch movements, tools and components.

There are a variety of demagnetizers available at a wide variety of price points. I use a mid-priced model that works instantly with a single button press (some less expensive models require you to slowly withdraw the item from the demagnetizing field, which can be a bit tricky and risks dropping or losing small parts).

In practice, I have rarely encountered a significant watch performance problem that was fully cured by demagnetizing alone, but it's a cheap and easy tool to use and thus easy to recommend as part of your toolkit.

Automatic Oilers

Automatic oilers are pen-like devices with a very fine, spring-loaded tip and a small oil reservoir. They are typically used to apply a precise amount of oil to the cap jewels of balance or other similar settings, through the hole jewel, without having to disassemble the setting, although they can also be used for other precise oiling tasks as well. These are more of a convenience than a necessity, but they can make certain oiling tasks much easier and more reliable - particularly oiling the cap jewels of non-shock-protected upper balance settings (since it is extremely challenging to reassemble these settings after oiling the cap jewel without displacing the oil).

I use the Bergeon 7718-1A oiler. These "real deal" Bergeon models are well-made, but pretty expensive. There are much cheaper knock-off alternatives available, but I can't vouch for their quality or reliability.

A couple of cautions when using these oilers:

Make sure to clean the tip of the oiler in between uses so that it is free of oil when you first insert it. Otherwise you will end up over-oiling or getting oil onto surfaces where it doesn't belong. I dab the tip in a block of melamine foam (magic eraser) for this purpose. The melamine does a good job removing oil without damaging the delicate tip, and it's cheap!

The tips are extremely delicate, so be very careful when handling them, especially when cleaning and when loading fresh oil into the reservoir (which requires removing and reinstalling the reservoir over the around the delicate tip). If you bend or break a tip, you can buy replacement tips (at least for the Bergeon models) for much less than the cost of a new oiler, but they are still not cheap.

The Bergeon Automatic Oiler. The closeup on the left shows the fine, retractable oiling tip and the clear oil reservoir. Filling the reservoir is a touchy operation, as it must be removed and reinstalled over the very delicate tip. Fortunately it holds what is practically a lifetime supply of 9010

Specialty Lubricants

I covered basic watch oils and greases in my Basic Tools guide, but as you get deeper into watchmaking you'll likely want to expand your lubricant collection to include some specialty oils and greases for specific applications.

Pallet Grease (Moebius 9415)

One of the keys to getting and maintaining good amplitude in a mechanical watch is minimizing friction in the escapement where the pallet stones contact the escape wheel teeth. Pallet grease, typically Moebius 9415, is a very light, low-viscosity grease that is specifically designed for lubricating the pallet stones while resisting migration to other parts of the escapement. There are various techniques for applying pallet grease, but the most common is to place a tiny amount, with a fine tip oiler, onto the face of the trailing pallet stone, then manually working the escape wheel back and forth to distribute the grease onto the escape wheel teeth. Be very sparing with the amount of grease you apply - a tiny amount goes a long way here, and too much grease can cause more harm than good (if you apply too much you can clean things up with careful application of Rodico).

Braking Grease

If you service automatic movements, you will need to apply a small amount of braking grease to the inner wall of the mainspring barrel before reinstalling the mainspring. This grease provides the correct balance of lubrication and friction to allow the bridle of the automatic mainspring to slip smoothly around the barrel wall when full winding tension is reached. There are a number of different braking greases available, and I have tried several. My current favorite is Kluber Chronogrease P125.

Epilam

Epilam (most commonly sold as Moebius Fixodrop) is a special immersion solvent that leaves behind a thin, invisible oleophobic coating that prevents oil migration. It is commonly used on pallet stones and escape wheels to keep pallet grease from migrating away from the intended contact surfaces. It can also be used on cap jewels or other surfaces where oil migration is a concern. It's a bit pricey, and not something you absolutely need, but it can definitely help extend the lifetime of a service.

A few tips on using Epilam with pallet stones and escape wheels:

While this is a bit controversial, I recommend keeping Epilam off of the impulse horn of the pallet fork (the part that contacts the impulse jewel), where it likely will do more harm than good. When I apply Epilam to pallet forks, I hold the fork in a pair of tweezers and carefully dip just the pallet stones into the solution.

Don't blow on Epilam coated parts to dry them, which can displace the coating. I use a heat dryer (the same one I use to dry parts after cleaning) to speed drying and also to help ensure that moisture doesn't get trapped under the Epilam coating.

When reassembling the escapement with Epilam coatings on the pallet stones and escape wheel, let the watch run for 10-15 minutes before removing the balance and applying pallet grease. This allows the Epilam to mechanically wear off of the surfaces where the pallet stones contact the escape wheel teeth, ensuring proper adhesion of the pallet grease to those areas.

Immersion Lubricants

You will occasionally run into parts, like certain automatic reversing wheels or calendar driving wheels, that have sub-components cannot be disassembled but which still need lubrication. In these situations, immersion lubricants such as Moebius Lubeta can be very useful. To use these, you simply dip the entire component, after cleaning, into the lubricant, allowing it to penetrate into the small gaps and interfaces between the sub-components. After a quick soak, the excess can be blown off and the part is then left to dry.

Note: Immersion lubrication, while beneficial, can sometimes leave parts with an unattractive film on surfaces that don't really need lubrication. I often find myself cleaning these surfaces with a bit of Rodico to restore their appearance.

Workholding, Handling, and Organization

Specialty Tweezers

While you can get a long way with a good set of standard tweezers, specialty tweezers that are designed for specific tasks or to handle particular components more safely and effectively can definitely make your life easier in some situations. There's an almost endless variety of specialty tweezers out there, but here are a couple variations that I find particularly useful:

Angle Tip Tweezers

These tweezers have tips that are bent at an angle (usually 45 or 90 degrees) to allow easier access to certain components or to allow you to manipulate parts from different angles. While they are reasonably versatile, I find them particularly useful in two specific situlations:

Manipulating the springs of certain shock-resistant jewel settings, particularly designs where the spring needs to be rotated, such as Seiko's Diashock system. The angled tips allow you to easily engage and rotate the springs.

Straightening or correcting bent hairsprings, where the angled tips allow you to approach the hairspring from above and gently manipulate it while avoiding contact with adjacent coils.

Note that, for these applications you'll often want to work with a pair of these angled tweezers, one in each hand, so get two!

Watch Hand Tweezers

These tweezers have very fine, flattened tips that allow you to safely and securely grip and manipulate watch hands without damaging them. They are particularly useful for handling small, delicate hands such as those found on subdials. While you can sometimes get by with standard fine-point tweezers, watch hand tweezers are a worthwhile investment if you frequently work with watches that have small or delicate hands.

My Horotec Watch Hand Tweezers. These really improve the watch-hand-installation experience

Holders and Vises

I will be delving a bit more into holders and vises in my Watch Case Restoration guide, but there are a few specialized holders, beyond the basic movement holder, that occasionally come in handy when working on movements.

Pin Vises

Pin vises are so fundamental and useful I almost added them to the Basic Tools Guide. They are essentially a small handheld chuck, similar to a drill chuck, that can be tightened around small cylindrical objects in order to hold them securely. They are great for clamping watch stems when you want to remove or install a crown, and also useful for holding mainspring arbors to help with insertion into barrels, particularly if the mainspring is wound a bit tightly around the arbor. They have many other uses as well, so I highly recommend picking up a quality set.

Pivot Vise

A pivot vise is a small vise, usually made of brass, with a knife-edge clamping surface drilled with a set of holes designed to hold wheel pivots and other small cylindrical objects like arbors or pinions securely without damaging or distorting them. I find myself reaching for this tool quite frequently, particularly to tighten loose watch hands. To do this, you close the vise, and then find the smallest pivot hole that will accept the collar of the hand. You can then open the vise slightly, move the hand to the next smaller hole, and gently close the vise to evenly squeeze and tighten the collar. This same approach can also work for tightening other similar objects including hairspring collets.

Contour Clamp

A contour clamp is a specialized holder that can securely grip small, irregularly shaped watch components, such as bridges or plates, without damaging them. It typically consists of a base with a matrix of spring loaded pins that conform to the shape of the irregular components that are pressed down into the pins. A knob can then be used to tighten the pins and lock the object in place. This allows you to work on certain irregularly shaped components, like automatic winding bridges, more easily.

Contour clamp holding a watch barrel bridge

Fractal Vise

They're a bit difficult to track down these days, but if you can get your hands on a small fractal vise they're fantastic for holding watch cases while doing work that requires significant leverage.

Storage

Watchmaking involves a lot of small parts and tools, so having a good storage system is essential to keep everything organized, protected. and easily accessible.

Storage Drawers and Bins

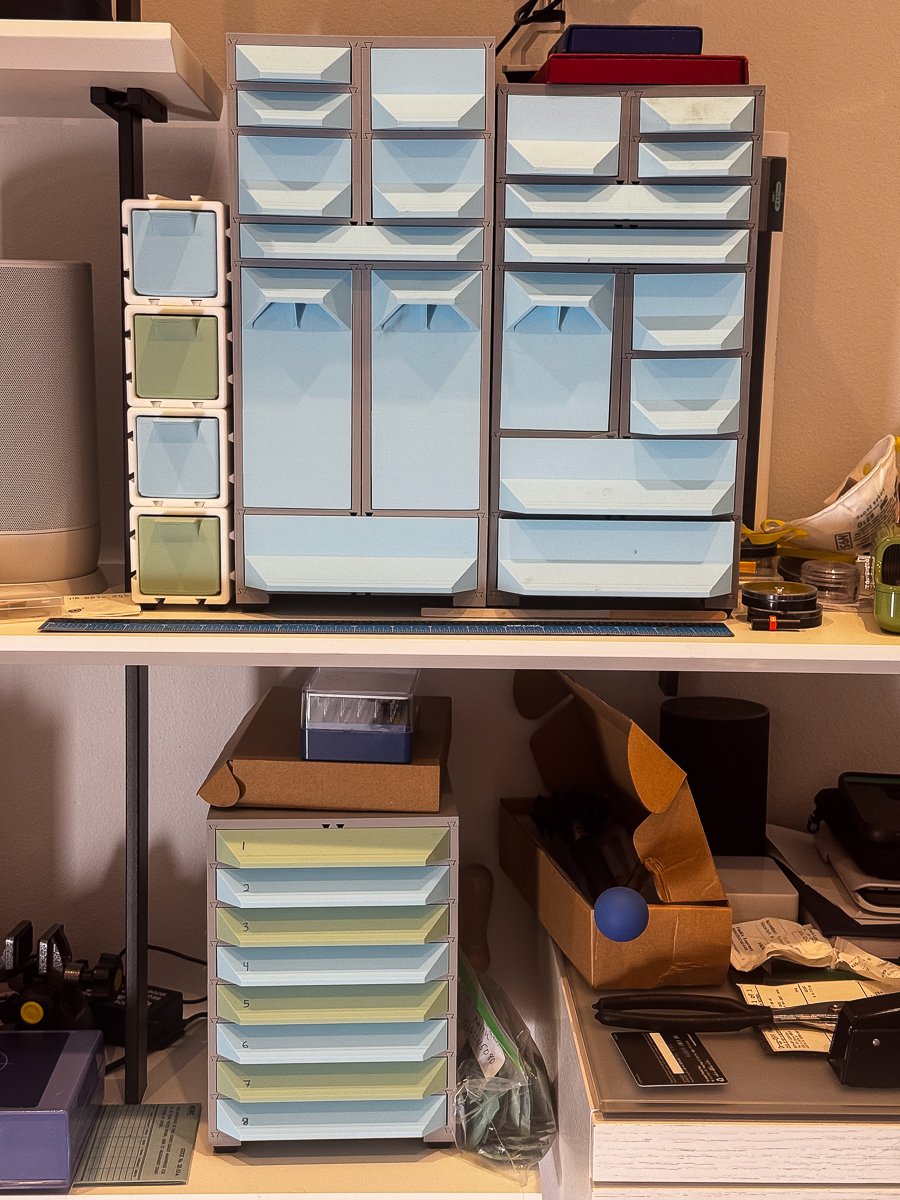

As your watchmaking hobby grows, keeping all of your tools, parts, supplies, donor movements, and partially completed projects organized becomes increasingly important. Organizers that offer a large number of small compartments for various things become something of a necessity. There are too many different options out there to recommend a specific product, but try to find something that suits your workspace layout, personal organizational style, budget and aesthetic preferences.

Some of my custom 3D printed parts and tool bins on shelves in my office. One of the great things about 3D printing storage drawers is that you can often adjust the dimensions of the model to suit specific purposes. For example, the set of 4 square drawers on the upper left are precisely sized to hold common replacement watch crystals.

Disposable Plastic Cases and Zip-lock Bags

It's also a good idea to keep a supply of small, disposable plastic cases and zip-lock bags on hand for storing, organizing, and protecting small parts and components. When I'm working on a watch movement, I typically store the case components in a small plastic container before placing them in a project drawer. These containers are also useful for storing small parts like spare screws or crowns, protecting movements during long term storage, and more.

Membrane Boxes

Membrane boxes are small plastic containers with a (usually transparent) flexible plastic film in the lid and body that encases small parts, preventing them from moving around when the box is closed. They are particularly useful for temporarily storing small, delicate items like watch hands while you work on a movement, since they prevent the parts from shifting around and potentially getting damaged.

Dial Holders

Dial holders are specialized containers used to securely hold watch dials during servicing or restoration. They typically are a round container with a flexible plastic structure inside that supports the dial, which a centering post built into the lid holds it in place. This keeps the dial fixed securely in the container while preventing the delicate upper surface from contacting anything.

A simple dial holder

Adhesives & Lume

UV Clear Adhesive

You'll want a good quality, clear UV-setting adhesive to set or re-set certain watch crystals that need to be glued in. This is typical for vintage tank-style cases, for example, as well as some pocket watches. This might make some traditionalists cringe, but it's actually a pretty good substitute for shellac to secure loose pallet stones and impulse jewels, although it can't subsequently be heat-softened to \ make further adjustments the way shellac can.

You'll also need a way to set the adhesive. I use a small-but-powerful UV flashlight for this purpose, but an inexpensive UV nail curing lamp can also work well if you have the space for it.

Superglue

Superglue, the bane of fingers everywhere. More generically known as cyanoacrylate adhesive, this quick setting, clear glue is useful in a variety of watchmaking applications. It can be used in some contexts where UV adhesive isn't practical because the bonded area can't be exposed to UV light. It can be used to create a very strong temporary bond between parts while a more permanent solution is implemented, and later can be removed easily with acetone (do be aware that acetone tends to damage plastics and will destroy acrylic crystals, on contact, so only use this trick when you are working purely with metal parts).

I've even used it successfully to remove stubborn case backs with non-standard designs that don't work with my removal tool by supergluing a small metal socket directly to the case back (later removing the socket and glue residue with acetone). It can be applied with precision using a watch oiler, as long as you work quickly. Just be careful when using superglue around delicate parts, as it can wick into tiny crevices and rapidly bond things you don't want bonded - especially skin!

Shellac

Shellac is a traditional adhesive used in watchmaking, primarily for securing pallet stones and impulse jewels, although it can also be used for other small components. It is heat-softenable, which has both advantages and disadvantages. The advantage is that it allows for adjustments after application as the shellac cools, as well as future adjustments or removal of the bonded component by applying heat to re-soften the shellac. The disadvantage is that the need to apply heat makes it more complicated to use that more modern adhesives like UV glue or superglue. It also is weakened by exposure to alcohol - particularly denatured alcohol.

Shellac is typically sold in flake form, and it rather inexpensive to purchase what is in essence a lifetime supply.

Shellac Heaters

To use shellac effectively, you'll need a way to heat it as well as the parts for application. There are a number of specialized shellac heaters available that are designed specifically for watchmaking tasks like securing or adjusting pallet stones or roller jewels. Vintage models with various configurations are easy to find on eBay.

Lume Kit

It's not uncommon for vintage watch hands to have degraded or missing lume. Alternatively, you may want to remove and replace radium or tritium lume in some cases to lessen the overall radiation levels of the watch, or to restore the lume's brightness and functionality. In these situations, you'll need a good lume kit. You'll want a variety of lume powders in various shades so you can match the aesthetic of the original lume as closely as possible, along with a good quality lume adhesive. It's helpful to select kits that come with lume powders formulated for use in vintage watches, so that they aren't overly bright or modern looking, but you can also use common alternatives, like coffee, to darken the lume a bit.

Maintenance and Fabrication

Screwdriver Maintenance Tools

Watchmakers' screwdrivers have fine tips that inevitably wear down or are damaged during normal use, which eventually makes them perform poorly. Quality screwdrivers will have replaceable tips, but it gets expensive to constantly replace them. As an alternative, you can maintain and restore the existing tips of your screwdrivers with a few specialized tools. There are a number of alternatives here, ranging from simple guides that work in conjunction with a sharpening stone to more elaborate tools and jigs. I use a sharpening tool that comes with a set of drop-in guides for various screwdriver tip sizes coupled with straightening and sharpening channels. I like this tool because it works quickly and puts a slight hollow grind on the tips, which helps them mate up better with thin slots in certain screws. Eventually you will have to replace tips as they are worn down by repeated sharpening, but this tool helps extend the life of my screwdriver tips significantly while improving their performance.

The tool I use to maintain my watch screwdrivers. It has multiple inserts to firmly hold different size screwdrivers with two positions, one for squaring the blade and another for sharpening it.

Drilling and tapping tools

If you're serious about watchmaking, sooner or later you'll encounter situations where you need to drill or tap small holes in movement or case components, whether to repair damaged threads, create new mounting points, or modify parts for custom applications. These are tools that I generally hope to avoid using if possible, but every so often I've needed them to salvage a difficult repair situation.

Watchmakers Tap & Die Set

I keep a simple tap and die set that covers many of the small sizes used for watch screws. I find that it is mostly useful to repair damaged threads in screw holes or on screws, although I've occasionally used it to create new threads as well. My set is small and inexpensive, but seems to work well enough for the occasional use. If you're doing a lot of custom work that involves drilling and tapping, you may want to invest in a higher quality set.

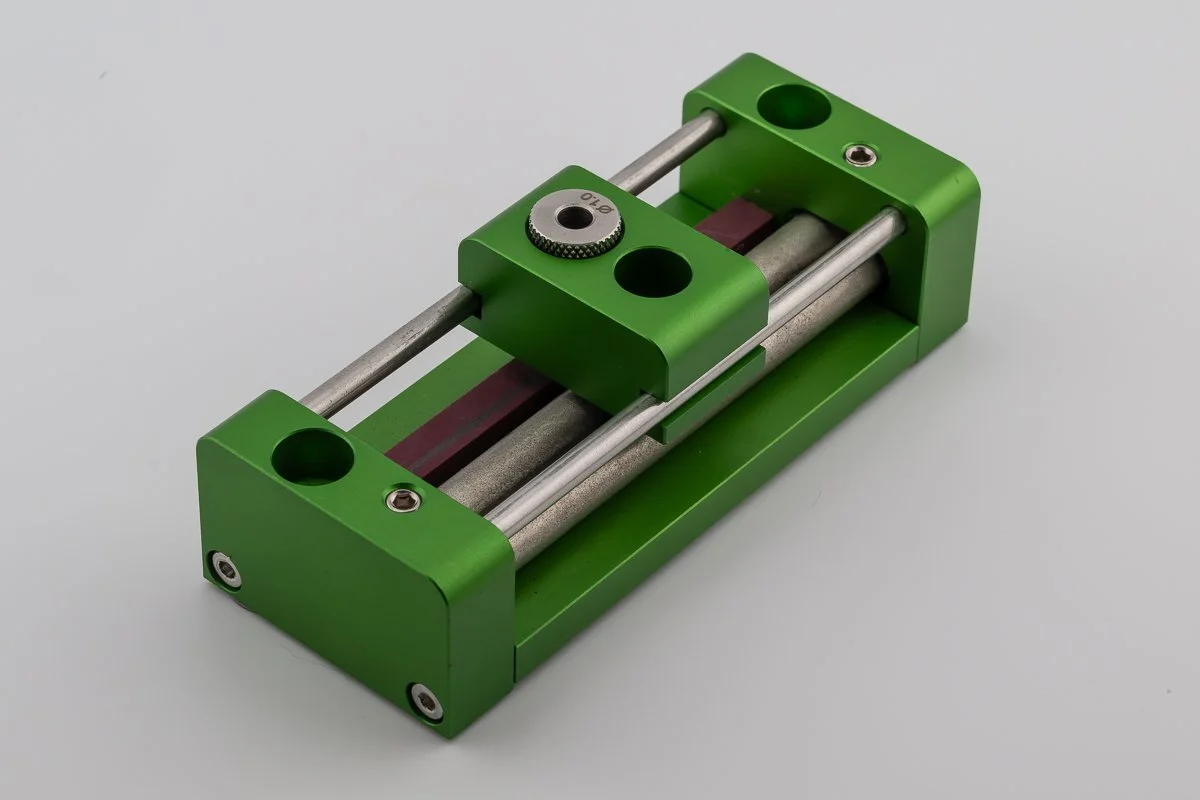

Precision Drill Press

A small, precision drill press is an essential tool for accurately drilling small holes in watch components. It provides stability and control, allowing you to drill straight and precise holes without damaging the surrounding material. Look for a model with adjustable speed settings and a fine depth stop for optimal control. An ER collet chuck also ensures flexibility to choose a wide variety of drill bit sizes. I have a moderately priced model, purchased from AliExpress, that has a nice precision clamping base and works well for my occasional needs.

One small tip on using drills with relatively tiny precision drill bits: they are quite delicate, and will snap rather easily if overheated or over-torqued. To avoid this, go slow, use light pressure, and periodically back the bit out of the hole to clear chips and allow cooling. Applying a bit of cutting oil can also help prolong bit life.

My precision drill press. Usefully, this comes with a pivot vise built in

Micro Screw Extractor

Unfortunately, broken screws are an occasional fact of life when restoring vintage "parts & repair" movements. I have run into a number of cases where a previous attempt at maintenance has resulted in a broken screw stuck in a plate or bridge (sometimes there has even been an attempt to address this by gluing parts back together, which rarely ends well. Acetone is a good thing to have handy to clean up these often-messy "repairs"). I've also broken a few screw heads myself. A micro screw extractor is the "first resort" when dealing with these situations. In fairness, I have found that these tiny extractors are not always successful, particularly if the screw body is deeply embedded or stuck, but they are worth trying before resorting to more tedious and destructive methods such as drilling out the screw.

My broken screw removal tool. It requires access to the screw body from both sides of the part, so it doesn’t work for screws holes that aren’t fully drilled (as in most mainspring arbors, for example)

3D Printing & CNC Machining

The final frontier for watchmaking is fabricating your own custom parts. As technology has advanced, 3D printing and CNC machining have become more accessible to hobbyists, opening up new possibilities for creating custom watch components.

3D Printing

While I wouldn't necessarily recommend investing in a 3D printer solely for watchmaking purposes, if you already have access to one or are considering the purchase, it can definitely be useful for watchmaking applications. Resin-based 3D printers have some advantages in the watchmaking context, since they can achieve higher resolution and finer details than filament-based printers, but FDM printers are more versatile and easier to use overall.

I have a FDM 3D printer (specifically, a Bambu model) that I have used with good success to print custom movement rings, jigs and holders, and most of my small storage drawers. Here are a few tips I've picked up along the way:

Use high-quality filament with good dimensional stability to ensure accurate prints. PETG is a good choice for many watchmaking applications due to its balance of strength, flexibility, durability and ease of printing. I would avoid PLA for functional parts, since it tends to be brittle and less durable.

Many FDM printers allow for extruders or nozzles with different sizes. Using a smaller nozzle is advantageous when printing small watch parts like movement rings.

While there are a number of interesting pre-made 3D models for watchmaking-related parts available online, you will likely need to create your own custom designs for many applications, so it pays to familiarize yourself with 3D modeling software or CAD tools. I use OnShape for most of my 3D modeling needs, but Fusion 360 and Tinkercad are also good options.

When designing your own custom parts, consider the limitations of your printer and the material you are using. Make sure to design-in appropriate tolerances to make sure parts will fit properly after printing. Of course, one of the great advantages of 3D printing is that if your part doesn't fit, you can adjust the model and try again relatively quickly and inexpensively, especially with small watch parts that tend to print quickly and consume a negligible amount of material.

CNC Machining

Accurate desktop CNC machines capable of fabricating small watch parts like gears are becoming increasingly capable and affordable. While I haven't yet personally invested in this technology, I am keeping a close eye on the space and will likely take the plunge at some point in the not-too-distant future. I'm really looking forward to a day where I can simply fabricate replacements for damaged or missing components, particularly for less common vintage movements where finding parts can be a challenge.